Product introduction:

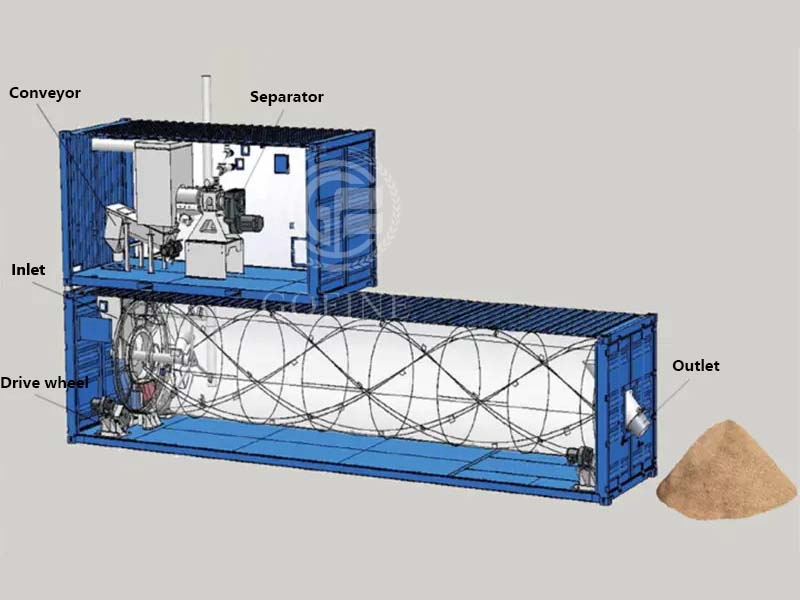

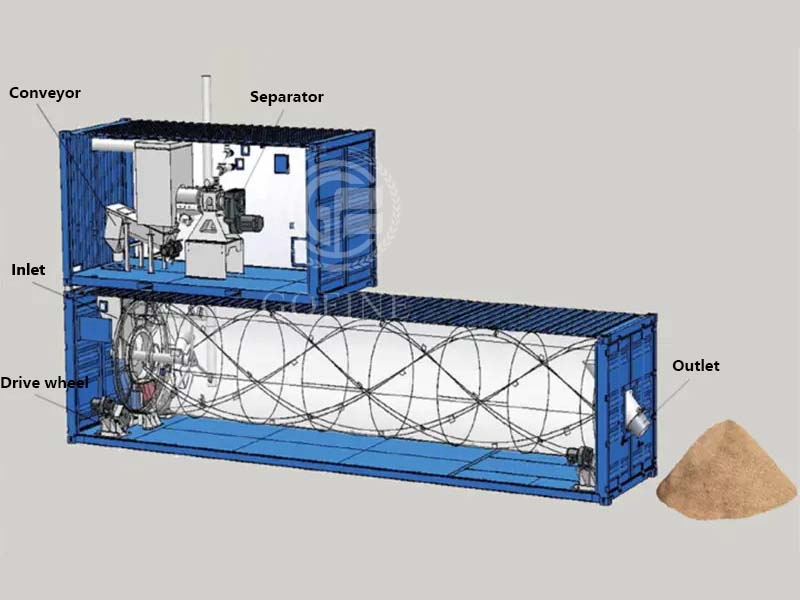

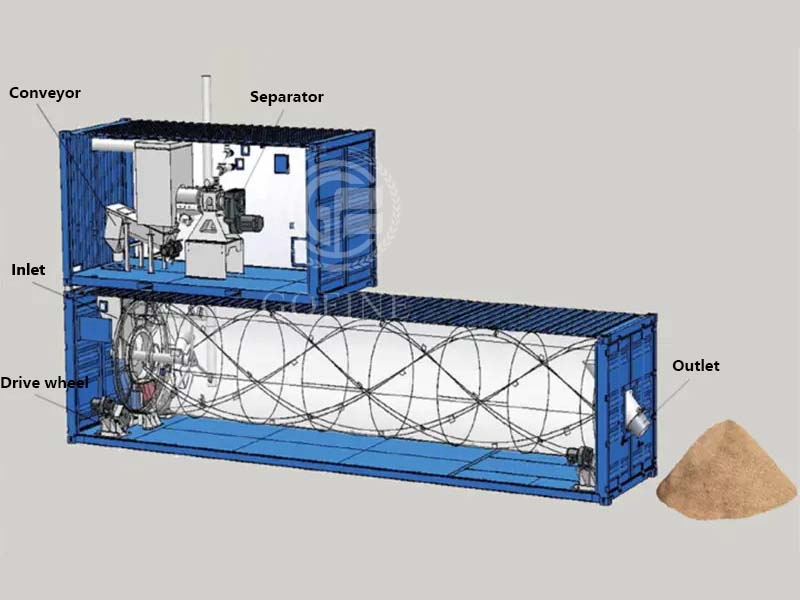

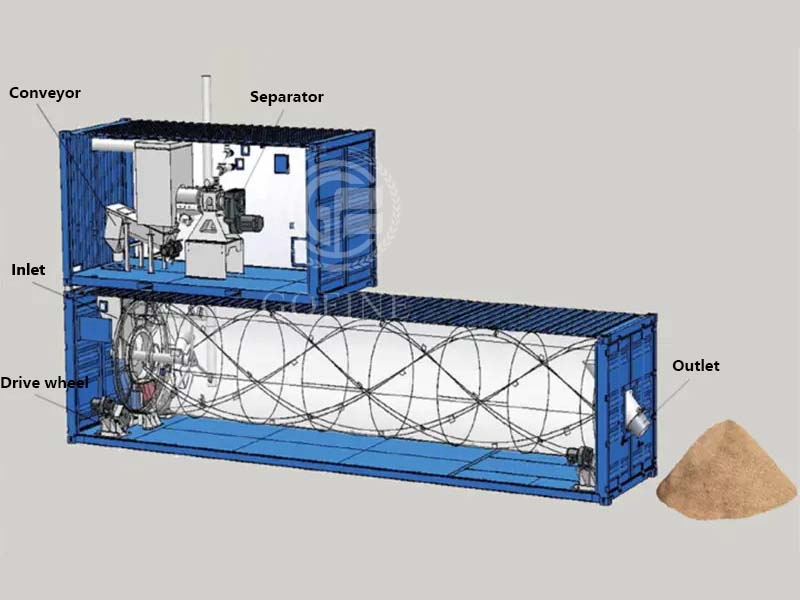

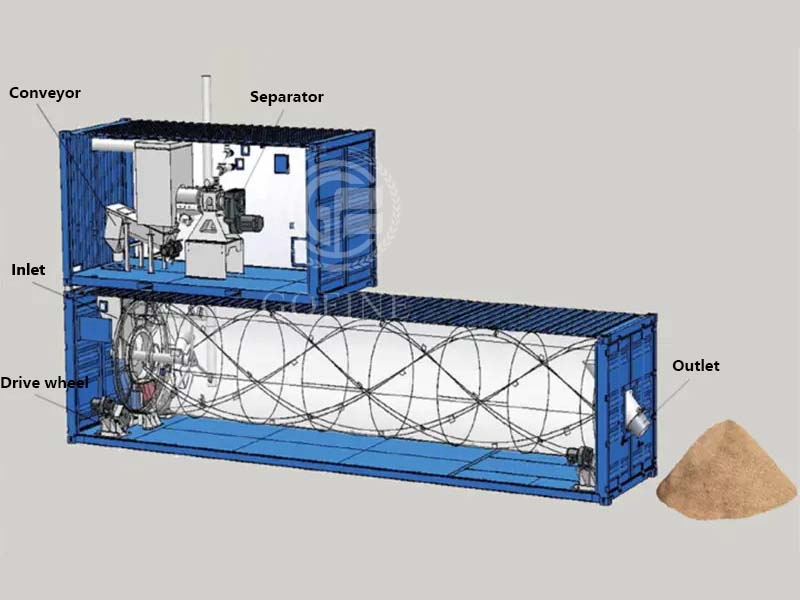

The cow bedding regeneration system is a system that separates undigested fiber from cow dung as organic bedding. The Cattle mattress regeneration system consists of a screw extrusion separator and a stainless steel fermentation tank. The daily production of bedding can be up to 48 cubic meters. The cow bedding regeneration system can realize the production of fresh organic bedding in the ranch, while reducing the storage space of manure.

Dry matter is separated from manure and separated by a dedicated solid-liquid separator. The separator separates the solid matter, reduces the water content, and then continuously transports it to the fermentation tank by a screw conveyor. The number of microorganisms is reduced by rapid high-temperature fermentation. The solid matter is subjected to high-temperature aerobic fermentation at a temperature of 52-75 degrees to reduce the number of harmful bacteria. The number of mastitis pathogens in the treated solid matter is greatly reduced.

The Cattle mattress regeneration system equipment can maintain high-temperature fermentation at 55-75℃ for 6-12 hours, with a manure sterilization rate of 99%. The moisture content of the produced cattle bedding is less than 50%, ensuring the safety, softness and comfort of the bedding. At the same time, the auxiliary drying module can be selected according to the original equipment of the ranch to improve the production efficiency of cattle bedding to the greatest extent. The daily bedding output of a single set of equipment is 40-60m3. The cattle bedding produced after fermentation is comfortable, environmentally friendly and safe, meeting the requirements for use as cattle bedding.

Scope of application:

Widely used in farms to produce fresh organic litter.

Main features:

1. It is dry, soft and comfortable, which can improve the lying rate of dairy cows, increase the lying time of dairy cows, and thus increase milk production.

2. Cow dung was originally waste, but it becomes a cow bedding material, which can reduce environmental pollution and has low cost.

3. It will not only not damage the limbs and hooves of dairy cows, but also promote blood circulation of dairy cows and ensure the health of dairy cows.

4. After using cow dung as cow bedding material, the feces produced by dairy cows in the future are easy to collect and clean, which reduces the difficulty of manure treatment.

5. The cattle farm no longer generates capital investment in bedding materials such as sand, reducing facility investment and operating costs.

Application:

Livestock and poultry manure.

Product images:

| Model |

GFNCG2300 |

| Total power of dry-wet separation (kw) |

13.7 |

| Total power of fermentation system (kw) |

12.55 |

| Fermentation time (h) |

24 |

| Cylinder speed (r/min) |

1.2 |

| Spindle speed |

65 |

| Reducer |

GAF99-2.2KW |

| Spiral reducer |

XW4-2.2-4P |

| Total capacity (m³) |

60 |

| Appearance size (mm) |

2300*14500 |