Biomass organic fertilizer production line

Home » Biomass organic fertilizer production line

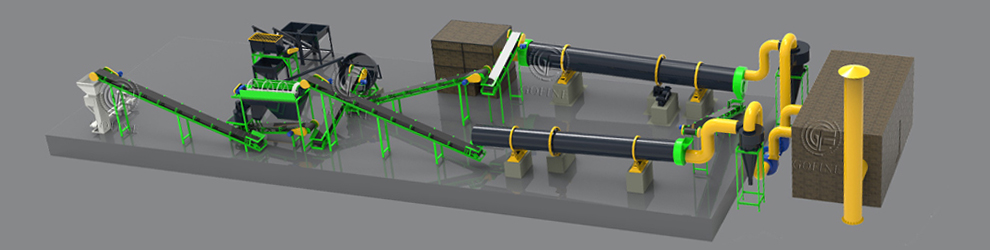

Biomass organic fertilizer production line

Application: Agricultural planting, flower planting, soil remediation, etc.

Applicable materials: Animal manure, crop straw, kitchen waste, food processing waste, etc.

Product Specifications: Support customization

Contact us

- Xingyang, Zhengzhou, China

- +86 151 3866 6240

- +86 137 3601 6895

- richard@zzgofine.com

Biomass organic fertilizer production line is a feed unit production line that uses biomass resources such as crop straw, livestock and poultry manure, etc. as raw materials and transforms them into high-efficiency organic fertilizers through a series of processing microbial fermentation technologies. The fertilizer produced by this organic fertilizer production line is not only rich in macroelements and trace elements, which can provide comprehensive nutrition for crops, but also has the function of improving soil structure and increasing soil fertility.

Raw material pretreatment: organic raw materials such as livestock and poultry manure, kitchen waste, straw, etc. are sorted, crushed, screened, etc. to remove impurities and large foreign matter.

Fermentation: The pre-treated organic raw materials are placed in the fermentation pile and fermented by adding bacteria, controlling temperature, ventilation and other measures.

Crushing: The fermented organic raw materials are crushed to meet the requirements of granulation, which is conducive to improving the utilization rate of fertilizers.

Mixing: The crushed organic raw materials are mixed to control their water content and nutrient ratio to ensure the quality and stability of the fertilizer.

Granulation: The mixed organic raw materials are formed by an organic fertilizer granulator to make organic fertilizer granules that meet national standards.

Screening: The granulated organic fertilizer is screened to select granules of different specifications to improve the quality and utilization rate of organic fertilizers.

Packaging: The screened organic fertilizer is packaged for easy storage, transportation and sales.

The applicable scale of biomass organic fertilizer production line is diverse and can be selected according to actual conditions. The following are some common scales:

Small scale

Annual output 1000-10000 tons: The required site area is about 8-15 mu, and the equipment configuration is relatively simple, mainly including fermentation turning machine, crusher, packaging machine, etc., which can meet the demand of small growers for organic fertilizer in a certain area.

Medium scale

Annual output 10,000-50,000 tons: The investment cost is relatively high, and it needs to be equipped with relatively complete fermentation, crushing, batching, mixing, granulation, screening and other equipment, and can establish long-term cooperation with large planting bases, agricultural parks, etc.

Large scale

Annual output 50,000-500,000 tons: It is usually the choice of large enterprises or groups, with a large investment scale, requiring a large site and complete production facilities. The production line of this scale has advanced equipment, high degree of automation, and fast production efficiency, which can meet the market demand of large agricultural planting areas or cross-regional markets.

Agricultural planting: It is widely used in the planting of various crops, such as grain crops, vegetables, fruits, flowers, etc. It can improve soil structure, improve soil fertility, and increase crop yield and quality.

Landscaping: It is used in landscaping projects such as urban parks, road greening, and golf courses to provide sufficient nutrients for flowers, plants, and trees, promote plant growth, and enhance plant resistance.

Soil improvement: For some poor and compacted soils, powdered organic fertilizer can increase the content of soil organic matter, improve soil aeration and water retention, make the soil more fertile and loose, and is conducive to the growth of crops.

Wide adaptability of raw materials

It can handle a variety of organic wastes, such as crop straw, livestock and poultry manure, forestry waste, food processing residues, etc.

Flexible and diverse production processes

Fermentation methods are diverse, either aerobic fermentation, anaerobic fermentation, or a combination of the two.

The granulation process is optional, and organic fertilizer granules of different shapes, sizes and strengths can be produced according to different market needs and product requirements.

High degree of automation

The production process is controllable, and an advanced automated control system is used to accurately control the transportation, mixing, fermentation, granulation, drying and other aspects of materials.

Reduce labor intensity, the application of automation equipment greatly reduces manual operations and improves production efficiency.

High product quality

Rich and comprehensive in nutrients, biomass organic fertilizer is rich in organic matter, nitrogen, phosphorus, potassium and medium and trace elements to meet the needs of crops at different growth stages.

Long-lasting and stable fertilizer effect: its nutrients are released slowly and have long-term effect, improving fertilizer utilization efficiency.

The effect of improving soil is significant: long-term use of biomass organic fertilizers can improve soil structure, increase soil fertility and fertilizer retention capacity, and improve the soil ecological environment.

| Item | Organic/Biological Organic Granules Fertilizer Production Line | ||||

| capacity | 10000mt/y | 30000mt/y | 50000mt/y | 100000mt/y | 200000mt/y |

| Area suggested | 30x10m | 50x20m | 80x20m | 100x20m | 150x20m |

| Payment terms | T/T | T/T | T/T/LC | T/T/LC | T/T/LC |

| Production time | 25 days | 35 days | 45days | 60 days | 90 days |

Prev: Crawler Film Rolling&Compost Turner Next: Powdered organic fertilizer production line