Product introduction:

The trough compost turner is a mechanical equipment used in the agricultural field, mainly used for the fermentation treatment of organic materials such as livestock and poultry manure and agricultural waste. It has the advantages of simple structure, convenient operation and low maintenance cost, and is suitable for large-scale organic waste treatment. The working principle of the trough compost turner is mainly to turn the compost by moving and turning the compost turning shovel device, thereby promoting the fermentation and maturity of the material.

Scope of application:

It is widely used in fermentation, ripening and moisture removal operations in organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, gardening fields and Agaricus bisporus cultivation plants.

Main features:

1. High efficiency of compost turning: The working length of the trough compost turning machine can reach 10m. With the help of the transfer vehicle, it can work in turns between multiple fermentation tanks.

2. Automatic control: The control cabinet is centrally controlled and can realize manual or automatic control functions.

3. Uniform compost turning: The structure is compact and stable, the process is advanced, and there is no slipping or jumping.

4. Strong adaptability: It is suitable for aerobic fermentation and can be used with solar fermentation rooms, fermentation tanks and transfer machines.

5. Long service life: The teeth of the trough compost turning machine are sturdy and durable, and have the ability to crush and mix materials.

6. Small footprint: The trough compost turning machine adopts a deep trough and long working distance design, which can effectively help customers save the area occupied by composting.

Application:

The trough type turning machine can be used for fermentation turning of organic waste such as livestock and poultry manure, sludge garbage, sugar factory filter mud, dregs cake, mushroom residue and straw sawdust.

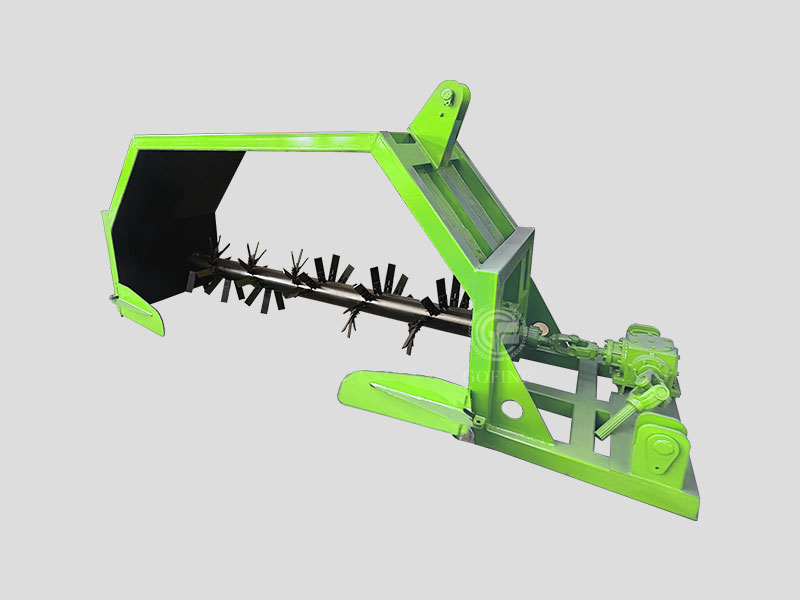

Product images

| Model |

Power (kw) |

Working speed (m/h) |

No-load speed (m/h) |

Turning depth (mm) |

Turning depth (mm) |

| GFCS-300 |

18.5 |

50 |

100 |

3000 |

1000 |

| GFCS-400 |

22 |

50 |

100 |

4000 |

1200 |

| GFCS-500 |

22*2 |

50 |

100 |

5000 |

1500 |

| GFCS-600 |

30*2 |

50 |

100 |

6000 |

1500 |