Product introduction:

Organic fertilizer drum dryer is mainly used in the production process of organic fertilizer granules. The drum dryer has high thermal efficiency and significant energy saving effect. The material in the inner cylinder exchanges heat with the hot air flow in the form of radiation, convection and conduction, which can evaporate the water in the organic fertilizer particles to meet production standards.

Working Principle:

The drum dryer mainly uses hot air to contact with organic fertilizer particles, thereby taking away the moisture in the organic fertilizer particles to achieve the purpose of drying. Usually after drying, the humidity of the granular organic fertilizer is about 13%. The conveyor belt sends the organic fertilizer particles into the dryer, and the exhaust gas generated by drying will enter the dust collector for evolution treatment. The dried organic fertilizer particles will be sent to the cooler for cooling.

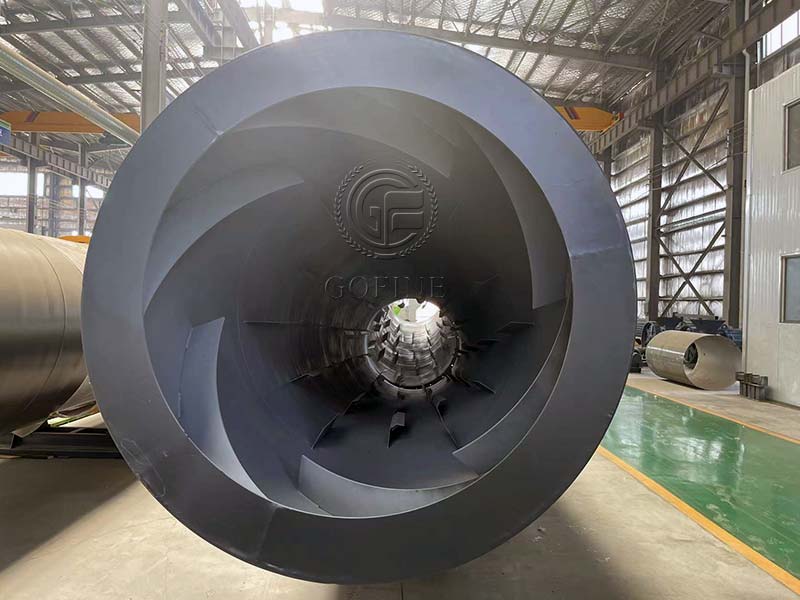

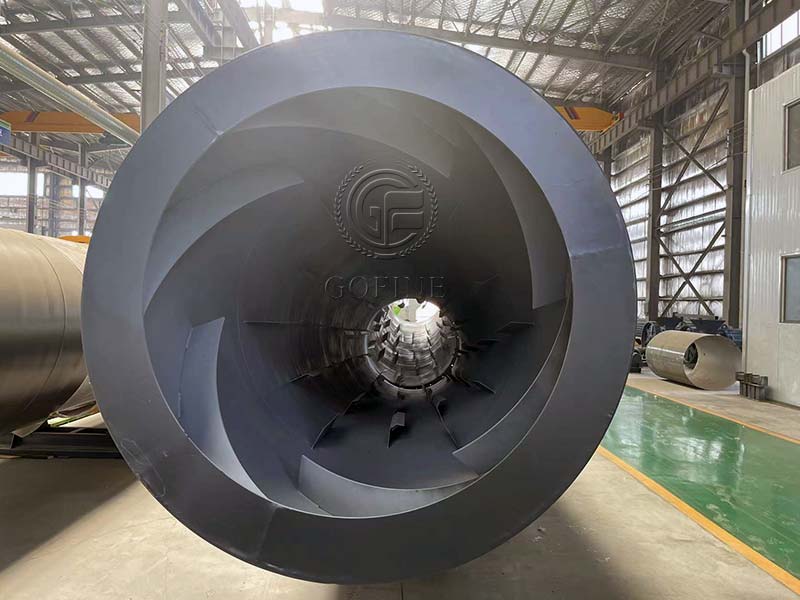

Equipment Structure:

The drum dryer consists of a rotary drum, a reducer and a motor. Multiple pads are set inside the drum to prevent the organic fertilizer particles from sticking to the inner wall. In addition, the rotary drum dryer is installed with a certain inclination angle (3-5 degrees), which allows the organic fertilizer particles to slowly pass through the drum during the drying process and be fully dried. The motor provides power for the rotation of the drum. At the same time, the reducer converts the power into a reasonable speed and increases the torque, thereby providing continuous power for the dryer.

Equipment Advantages:

1. The rotary drum dryer has a high degree of mechanization and a large production capacity.

2. The resistance of the fluid passing through the drum is small and the functional consumption is low.

3. It has strong adaptability to material characteristics.

4. The operation is stable, the operating cost is low, and the product drying uniformity is good.

Product images:

| Product specifications |

Motor power (kW) |

Reducer model |

Intake temperature (℃) |

Installation tilt angle (degrees) |

Speed (r/min) |

Production capacity (t/h) |

| GFHG-0808 |

5.5 |

ZQ250 |

≥300 |

3-5 |

6 |

1-2 |

| GFHG-1010 |

7.5 |

ZQ350 |

≥300 |

3-5 |

6 |

2-4 |

| GFHG-1212 |

7.5 |

ZQ350 |

≥300 |

3-5 |

6 |

3-5 |

| GFHG-1515 |

11 |

ZQ400 |

≥300 |

3-5 |

6 |

4-6 |

| GFHG-1616 |

15 |

ZQ400 |

≥300 |

3-5 |

6 |

6-8 |

| GFHG-1818 |

22 |

ZQ500 |

≥300 |

3-5 |

5.8 |

7-12 |

| GFHG-2020 |

37 |

ZQ500 |

≥300 |

3-5 |

5.5 |

8-15 |

| GFHG-2222 |

37 |

ZQ500 |

≥300 |

3-5 |

5.5 |

8-16 |

| GFHG-2424 |

45 |

ZQ650 |

≥300 |

3-5 |

5.2 |

14-18 |