Product introduction:

Crawler compost turner is also called crawler compost turner. Crawler compost turner adopts straddle structure. After working, it will form a new strip pile, and there is no need to spend manpower to organize the fertilizer pile. Compared with walking compost turner, it has more power. The overall structure of crawler compost turner is reasonable, the force is balanced, it is easy to control, and it has stronger adaptability to the site. At the same time, this crawler compost turner is equipped with a cab, which can isolate the heat and odor generated by composting, which is very friendly to operators.

Scope of application:

It is widely used in manure treatment in organic fertilizer plants, compound fertilizer plants, and large farms.

Main features:

1. Advanced technology: crawler compost turner has the characteristics of high material accumulation and large composting output. The composting spacing is 0.8-1 meter and the composting height is 0.6-1.8M.

2. Balanced power: The composting clutch of this organic fertilizer compost turner adopts soft start, the drum is hydraulically lifted, and the fermentation is sufficient and the pollution is small.

3. Reduce costs: crawler composting machines are suitable for strip composting, which can save infrastructure projects, save space, save investment costs, and facilitate expansion.

4. Reasonable structure: The unique track design not only changes the disadvantage of low output of traditional composting machines that simply use light rails, but also overcomes the disadvantage of high cost of transmission accessories of conventional rack and light rail composting machines.

5. Convenient operation: Our organic fertilizer composting machine has the advantages of low energy consumption, easy control, shortened working time, and short fermentation cycle.

Application:

It can be used for composting livestock and poultry manure such as pig manure, cow manure, sheep manure, as well as agricultural waste such as straw, rice husks, and mushroom residues

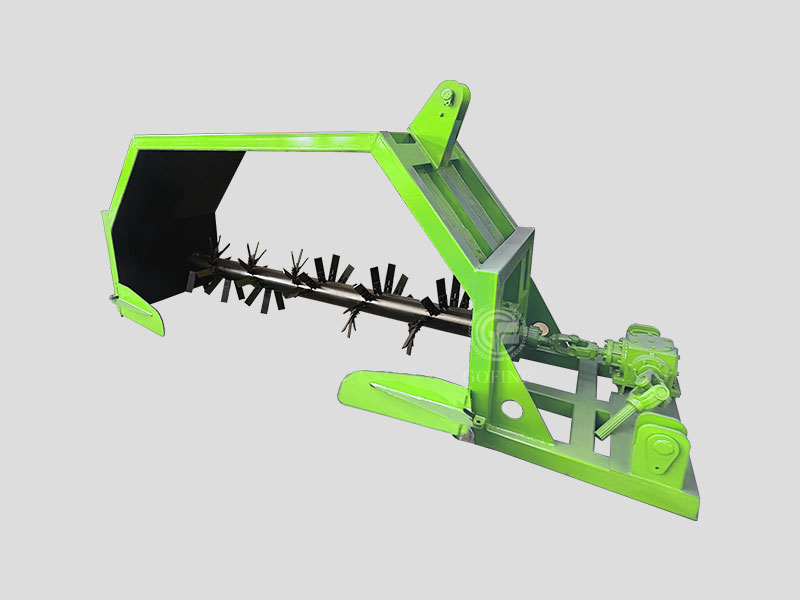

Product images

| Model |

GFLD-L2500 |

GFLD-L2600 |

GFLD-L2800 |

GFLD-L3000 |

GFLD-L3200 |

| Turn width (mm) |

2500 |

2600 |

2800 |

3000 |

3200 |

| Turn height (mm) |

800-1100 |

1000-1300 |

1000-1300 |

1000-1300 |

1300-1500 |

| Pile row spacing (mm) |

800-1000 |

800-1000 |

800-1000 |

800-1000 |

800-1000 |

| Power (kw) |

65 |

85 |

88 |

115 |

132 |

| Speed (r/min) |

2400 |

2400 |

2400 |

2400 |

2400 |

| Working speed (m/min) |

5-10 |

5-10 |

5-10 |

5-10 |

5-10 |

| Working capacity (m³/h) |

800-1000 |

900-1100 |

1000-1200 |

1200-1500 |

1300-1600 |

| Dimensions (mm) |

3500×2650×2800 |

3800×2800×3000 |

4000×2800×3000 |

4200×2800×3000 |

4400×2800×3200 |