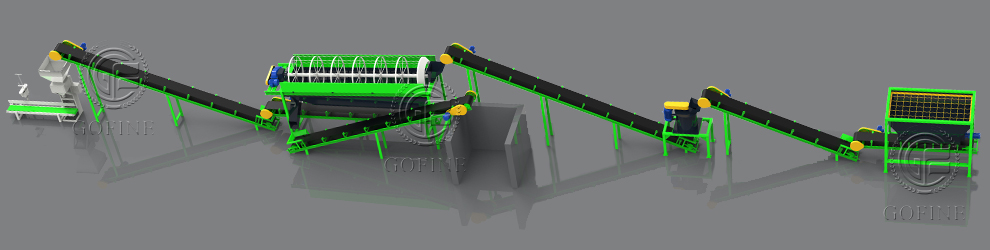

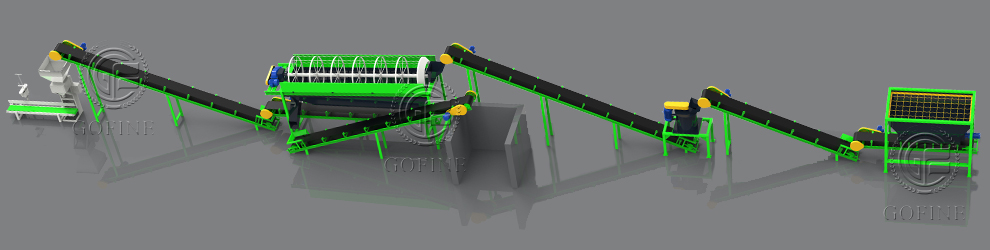

The powdered organic fertilizer production line is a professional production system that converts organic waste, such as crop straw, livestock and poultry manure, domestic garbage, urban sludge, etc., into high-quality powdered organic fertilizer through a series of processing procedures such as fermentation, crushing, screening, and packaging.

Production process:

Raw material collection and pretreatment: Collect various organic wastes, such as chicken manure, cow manure, straw, etc. Pre-treat the raw materials, such as removing large impurities, adjusting the moisture content, etc., so that the raw materials are suitable for entering the fermentation stage.

Fermentation: Put the pretreated raw materials into the fermentation equipment, add an appropriate amount of fermentation bacteria, control the temperature, humidity, ventilation and other conditions, and perform aerobic fermentation.

Crushing: The fermented materials are crushed by the crushing equipment to crush the large pieces of materials into fine particles.

Screening: The crushed materials enter the screening equipment to screen out the powdered organic fertilizer products that meet the particle size requirements.

Stirring and mixing: If other nutrients or additives need to be added, stir and mix them thoroughly in the stirring and mixing equipment.

Packaging: The powdered organic fertilizer that has been stirred and mixed evenly is transported to the packaging equipment and packaged according to the set weight.

Production scale

The production scale of this production line is flexible and diverse. The output of a small production line can reach 1-2 tons per hour, the output of a medium-sized production line is about 3-5 tons per hour, and the output of a large production line can exceed 5 tons per hour. It can be selected according to market demand and investment scale.

Applicable raw materials

Application areas

Agricultural planting: It is widely used in the planting of various crops, such as grain crops, vegetables, fruits, flowers, etc. It can improve soil structure, improve soil fertility, and increase crop yield and quality.

Landscaping: It is used in landscaping projects such as urban parks, road greening, and golf courses to provide sufficient nutrients for flowers, plants, and trees, promote plant growth, and enhance plant resistance.

Soil improvement: For some poor and compacted soils, powdered organic fertilizer can increase the content of soil organic matter, improve soil aeration and water retention, make the soil more fertile and loose, and is conducive to the growth of crops.

Main features

Fine fermentation: Using advanced fermentation technology, during the tank fermentation process, the compost turner operates regularly to ensure that the material is evenly heated and fully in contact with the air, accelerating the fermentation process and improving the fermentation effect.

High degree of automation: Using advanced control systems, it can realize automatic control of the entire production process, improve production efficiency and product quality stability.

Flexible production: According to different raw materials and market demands, the production formula and process parameters can be flexibly adjusted to produce a variety of powdered organic fertilizers with different nutrient contents and functions.

Wide adaptability: It can accept various types of organic waste as raw materials, including livestock and poultry manure, crop straw, urban organic garbage, food processing waste residue, etc.