Efficient fermentation of organic fertilizer – horizontal fermentation tank

News April 15, 2025

Faced with the problems of long traditional composting cycle, heavy pollution and uneven maturity, Gofine organic fertilizer horizontal fermentation tank uses intelligent temperature control and efficient mixing technology to compress the fermentation cycle from 30 days to 7-10 days, creating core competitiveness for organic fertilizer companies to reduce costs and increase efficiency.

Triple technological breakthroughs to accelerate the fermentation process

The equipment adopts a 304 stainless steel double-layer tank body, built-in patented stirring shaft and variable frequency drive system, and realizes 360° no-dead-angle turning of materials through positive and reverse alternating stirring. The intelligent PLC control system monitors temperature, humidity and oxygen content in real time. When the temperature in the tank reaches 55℃, it automatically starts ventilation and cooling to ensure that thermophilic bacteria continue to efficiently decompose organic matter. Actual measured data shows that after 7 days of fermentation of mixed materials such as chicken manure and straw, the organic matter conversion rate exceeds 65%, far exceeding the level of traditional composting.

Environmentally friendly closed loop, zero pollution in production

The fully enclosed fermentation chamber is equipped with a deodorization and filtration system to increase the absorption rate of harmful gases such as ammonia and hydrogen sulfide to 98%, eliminating secondary pollution. There is a leachate recovery device at the bottom of the tank, which can be recycled for material humidity adjustment after biological treatment to achieve zero waste of resources. After a breeding enterprise in Hebei introduced this equipment, it processed 20,000 tons of livestock and poultry manure annually and produced 12,000 tons of high-quality organic fertilizer simultaneously, and was certified as a provincial environmental protection demonstration project.

Flexible adaptation, full scene coverage

From family farms to large-scale enterprises, the equipment provides a variety of specifications of 5-200 cubic meters. The modular design supports multi-tank parallel operation to meet different production capacity requirements. The touch screen operation interface simplifies the management process, and novices can get started in 30 minutes, with only one person on duty per day. Now we are launching a “trade-in” activity, replacing traditional fermentation equipment with up to 30,000 yuan, and the first 20 signed customers will enjoy 3 years of free strain supply.

The green agricultural outlet has arrived, and the horizontal fermentation tank reshapes the organic fertilizer production model with the power of technology. Contact us now to make an appointment for free capacity calculation and unlock a new fermentation solution that is efficient, environmentally friendly and intelligent!

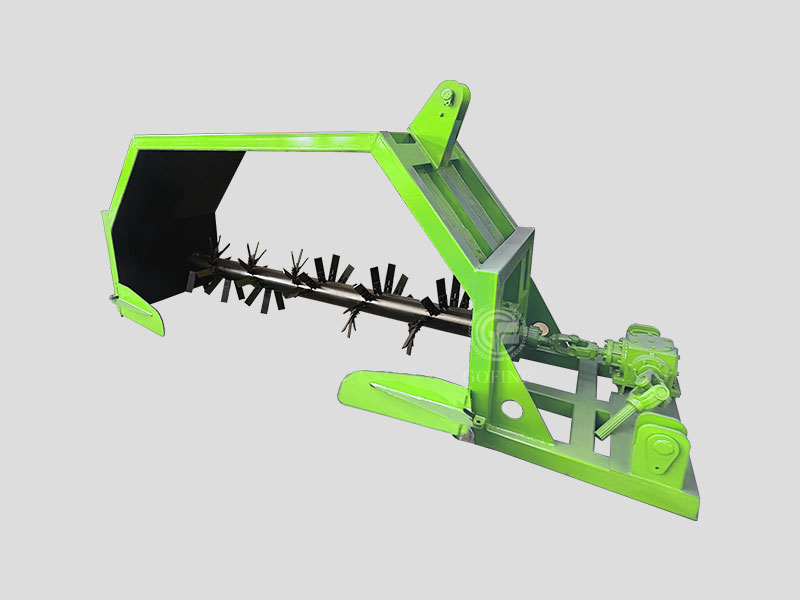

Prev: High efficiency spiral cow dung dehydrator equipment Next: Tracked compost turner with film rolling function