Fermentation Tank and Tracked compost turning machine Fermentation Schemes

News January 12, 2026

Organic Fertilizer Fermentation Plan

I. Advantages of Horizontal Fermentation Tanks (Trough Fermentation System)

Core Advantages: Space-efficient, controllable process, environmentally friendly.

1. Small footprint, high space utilization:

The equipment uses a three-dimensional trough structure, which can fully utilize vertical space. The ground area required to process the same amount of material is far less than that of windrow composting.

Particularly suitable for areas or projects with limited land resources and factory space.

2. Highly controllable fermentation process, high efficiency:

Precise temperature control: The tank is usually equipped with forced ventilation and temperature monitoring systems, which can more accurately control oxygen supply and temperature, allowing the material to quickly enter and maintain a high-temperature phase (55-65℃), killing pathogens and weed seeds, and shortening the fermentation cycle (usually 15-30 days).

Even turning: Mechanized stirring devices (such as chain plate type, screw type) provide thorough turning, ensuring uniform material mixing and better fermentation consistency.

3. Less affected by weather, can operate year-round:

The equipment operates inside a factory building, unaffected by adverse weather conditions such as rain, snow, and strong winds, enabling stable and continuous production.

4. High degree of automation, low labor requirements:

From feeding, turning, ventilation to discharging, a high degree of mechanization and automation can be achieved, reducing labor intensity and labor costs.

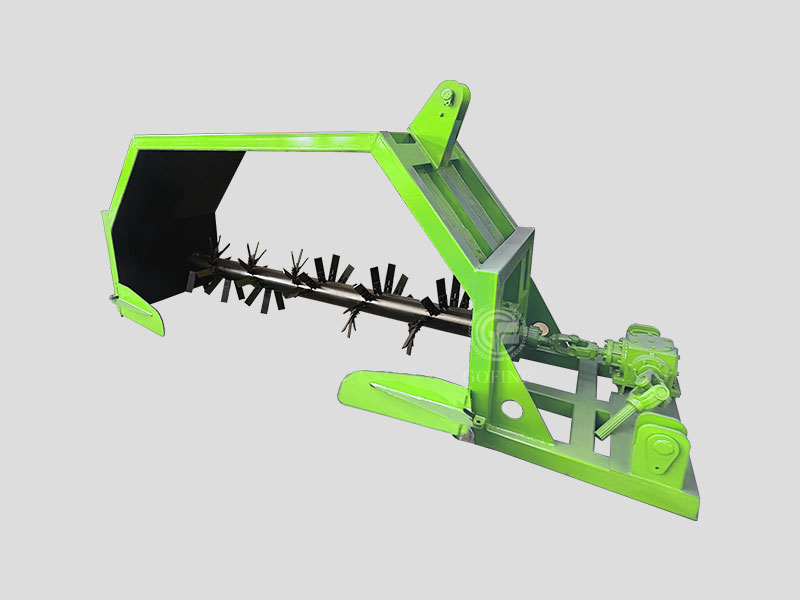

II. Advantages of Crawler-type Windrow Turners (Windrow Composting)

Core Advantages: Flexible investment, large processing capacity, intuitive operation, strong adaptability.

1. Low initial investment cost:

The system structure is simple, the main equipment is the windrow turner and the site (which may only require simple hardening). The infrastructure and equipment investment are far lower than that of horizontal fermentation tanks, making it an ideal entry-level option for small and medium-sized farms or projects.

2. Large and flexible processing capacity:

By adjusting the number and size of windrows, it can easily handle material quantities ranging from tens of tons to tens of thousands of tons, which is very flexible.

Suitable for scenarios with large seasonal fluctuations in raw materials (such as agricultural harvest seasons).

3. Simple and intuitive operation and maintenance:

The technical threshold is low, and operators are easy to understand and master. Equipment maintenance is also relatively simple, and the professional requirements for the operation and maintenance team are not high. 4. Good adaptability to materials:

It is particularly suitable for processing bulky and well-structured materials such as crop stalks and garden waste. The windrow composting method provides good natural ventilation and prevents compaction.

It has relatively loose requirements for material particle size and moisture content, resulting in a higher tolerance for variations.

5. No “single point of failure” risk:

Even if one composting machine malfunctions, other equipment or manual labor can temporarily replace it without affecting the fermentation process of other windrows, resulting in high system reliability.

How to choose:

Choose a horizontal fermentation tank if: you have a sufficient budget, strict environmental protection requirements (especially near residential areas), limited space, and you pursue efficient, stable, and automated production, and the materials to be processed may have strong odors (such as municipal sludge and kitchen waste).

Choose a crawler-type windrow turner if: you have limited initial capital, have ample space, mainly process agricultural waste, need to flexibly adjust the processing volume, and can accept certain environmental impacts and a longer fermentation cycle.

In short, both are mature fermentation technologies, and there is no absolute superiority or inferiority. The key is to make the most suitable choice based on the specific budget, environmental protection requirements, site conditions, material characteristics, and operational goals of the project.

Prev: How Trough-Type Compost Turner Transform Animal Manure into High-Yield Organic Fertilizer Next: Chicken Manure Fermentation and Granulation Production Line: Transforming Waste into Commercial-Grade Organic Fertilizer