Chicken Manure Fermentation and Granulation Production Line: Transforming Waste into Commercial-Grade Organic Fertilizer

News January 6, 2026

Facing the pressure of environmentally friendly treatment of livestock and poultry manure and the growing demand for organic fertilizers, efficiently converting chicken manure into high-value commercial fertilizer has become a new profit growth point for breeding enterprises and fertilizer processing plants. Our integrated fermentation and granulation production line, specifically designed for the resource utilization of chicken manure, is helping global customers achieve a win-win situation of environmental compliance and economic benefits, transforming waste materials into uniform, high-quality commercial organic fertilizer granules.

Professional Process, Efficient Conversion

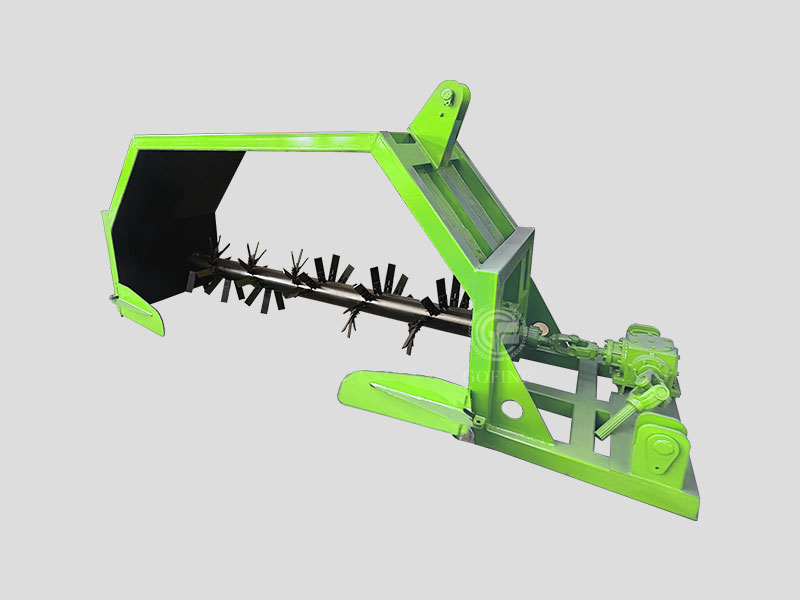

This production line adopts a mature process of trough-type high-temperature aerobic fermentation + high-efficiency granulation. The front end is equipped with heavy-duty composting equipment, which, through precise oxygen supply and temperature control, quickly completes the harmless treatment and maturation of chicken manure within 15-20 days, completely eliminating pathogens, weed seeds, and odors. The back end is connected to a dedicated organic fertilizer granulator, which can produce granules with high strength and good roundness, greatly improving the marketability and added value of the product.

Intelligent Integration, Wide Application

The entire line is designed to be compact and reasonable, realizing continuous production from raw material pretreatment, fermentation, crushing, mixing, granulation to drying, cooling, screening, and coating. The resulting granular organic fertilizer has balanced nutrients and meets organic farming standards. It is suitable for field crops, vegetable and fruit orchards, landscaping, and soil improvement projects, effectively improving soil structure and promoting crop growth.

Reliable Quality, Durable and Energy-Saving

Core equipment such as the composting machine, granulator, and dryer all adopt heavy-duty designs. Key contact parts use special wear-resistant and corrosion-resistant materials to ensure long-term stable operation in highly corrosive and abrasive environments. The system’s heat energy recycling design significantly reduces energy consumption, making the production process more economical and environmentally friendly.

Comprehensive Service, Worry-Free Guarantee

We provide comprehensive technical support from site planning, process design, installation and commissioning to personnel training, and have established a complete global after-sales service network to ensure timely supply of spare parts and quickly resolve production problems through remote guidance and on-site services, ensuring the continuous and efficient operation of the production line.

Choosing our chicken manure fermentation and granulation production line is not only an investment in a set of production equipment, but also a strategic choice to lay out the future of circular agriculture. It transforms environmental responsibility into sustainable profits, helping you gain a head start in the development of green agriculture.

Prev: Fermentation Tank and Tracked compost turning machine Fermentation Schemes Next: Integrated Production Line for Chicken and Cow Manure Fermentation and Granulation: Empowering Green and Circular Agriculture