Integrated Production Line for Chicken and Cow Manure Fermentation and Granulation: Empowering Green and Circular Agriculture

News December 29, 2025

Facing the dual pressures of environmentally friendly treatment and resource utilization of livestock and poultry manure, an efficient and stable organic fertilizer production line has become crucial for the transformation and upgrading of modern livestock farms and fertilizer processing plants. Our integrated fermentation and granulation organic fertilizer production line, specifically designed for raw materials such as chicken and cow manure, is helping global customers convert waste materials into commercial-grade organic fertilizer granules, achieving a win-win situation for environmental protection and profitability.

Core Technology, Efficient Conversion

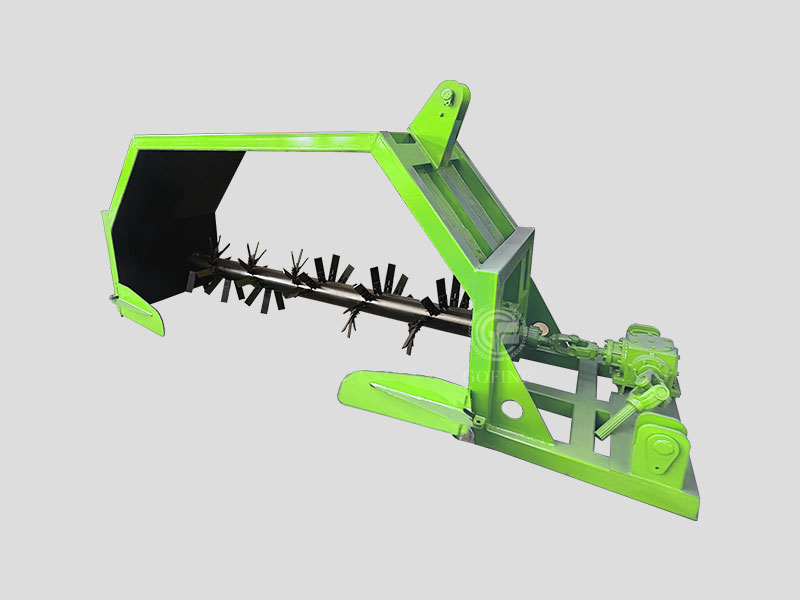

This production line adopts a mature process of trough-type aerobic fermentation + high-efficiency granulation. The front end is equipped with a heavy-duty crawler-type compost turning machine, which efficiently and evenly provides oxygen and turns the mixed manure and auxiliary materials. Intelligent control of temperature and humidity ensures rapid harmless treatment and maturation, completely eliminating odors and pathogens. The back end is connected to a dedicated organic fertilizer granulator, which can produce granules with high strength and good roundness, facilitating storage, transportation, and mechanized fertilization.

Intelligent and Integrated, Wide Range of Applications

The entire line is compactly designed and highly automated. From raw material pretreatment, fermentation, crushing, mixing, granulation to drying, cooling, screening, and coating, continuous production is achieved. The resulting granular organic fertilizer is of stable quality, meeting organic farming standards, and is suitable for field crops, cash crops, landscaping, and soil improvement, effectively increasing soil organic matter and achieving slow-release and long-lasting nutrient supply.

Excellent Quality, Durable and Reliable

The core equipment, such as the compost turning machine, granulator, and dryer, all feature heavy-duty design and anti-corrosion and rust-proof treatment. Key components use high-strength wear-resistant materials, ensuring long-term stable operation in corrosive and high-wear environments, with low failure rates and economical maintenance costs.

Comprehensive Service, Worry-Free Guarantee

We provide comprehensive technical support, from site planning and process design to installation, commissioning, and personnel training. Backed by our global service network, we provide timely spare parts supply and remote technical guidance, ensuring the production line quickly reaches full capacity and operates stably, making us your trusted long-term partner in developing circular agriculture.

Choosing our organic fertilizer production line is not just an investment in a set of equipment, but also an investment in a core asset for the future of green agriculture. It allows for the repurposing of organic waste, helping you achieve both economic benefits and environmental reputation in this era of sustainable development.

Prev: Chicken Manure Fermentation and Granulation Production Line: Transforming Waste into Commercial-Grade Organic Fertilizer Next: Organic Fertilizer Fermentation Equipment: Your Best Partner for Organic Waste Resource Utilization