Intelligent and efficient chicken manure fermentation tank

News July 1, 2025

At a time when the scale of chicken farming is booming, improper handling of chicken manure can easily cause environmental pollution, while scientific utilization can transform it into valuable resources. Our chicken manure fermentation tank, with its innovative technology and excellent performance, has become an ideal equipment for efficient fermentation of chicken manure and turning waste into treasure, providing green and environmentally friendly solutions for global customers.

Fully sealed fermentation, isolated from pollution and more at ease. The chicken manure fermentation tank adopts a horizontal fully sealed design, with a double-layer insulation tank body and a professional deodorization device to prevent the overflow of harmful gases such as ammonia and hydrogen sulfide from the source, and the odor removal rate is as high as 90%, effectively improving the surrounding environment. At the same time, the sealed environment creates stable fermentation conditions for microorganisms, avoids interference from external bacteria, ensures that the chicken manure is fully decomposed, and the organic fertilizer produced is safe and harmless with excellent quality.

Intelligent and precise control makes the fermentation process more worry-free. The horizontal fermentation tank is equipped with an intelligent control system, with built-in high-precision temperature, humidity and oxygen concentration sensors to monitor the fermentation status in the tank in real time. When the temperature is too high or the oxygen is insufficient, the system automatically starts the stirring, ventilation, water replenishment and other procedures to accurately control the fermentation parameters to ensure that the microorganisms are always in the best active state. Users can also remotely view the operation data and adjust the process settings through the mobile phone APP. Even cross-border management can easily grasp the fermentation progress, making the complex fermentation process simple and efficient.

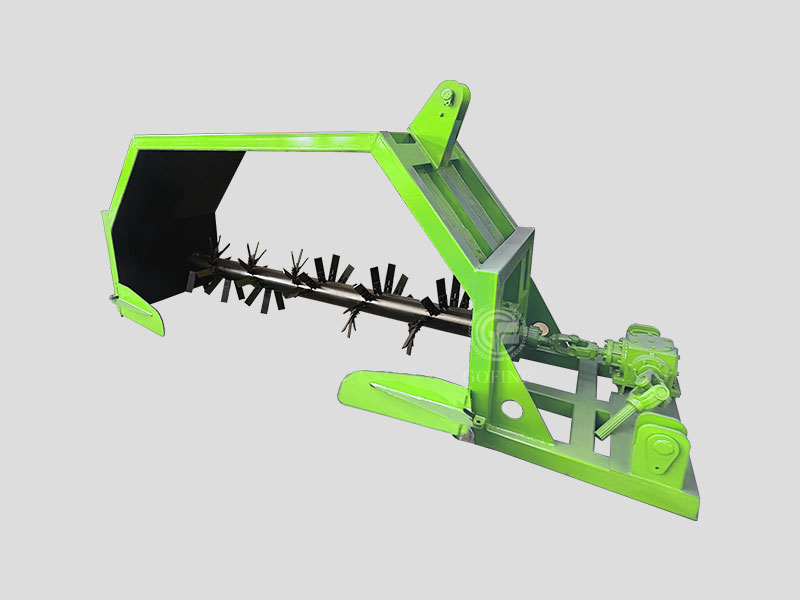

Efficient and fast fermentation, more significant increase in production capacity. The unique internal stirring device and heat circulation system make the chicken manure fully turned in the tank and heated evenly, and the fermentation efficiency is increased by 70%. Traditional composting requires a fermentation cycle of 20-30 days, but it can be completed in only 7-10 days in the chicken manure fermentation tank, greatly shortening the production time. A single tank can process 3-10 tons of chicken manure per day, meeting the needs of breeding enterprises of different sizes, and quickly converting chicken manure into high-quality organic fertilizer rich in humus, nitrogen, phosphorus and potassium and other nutrients, realizing efficient resource utilization.

Real cases witness strength. After a large chicken farm in Africa introduced a chicken manure fermentation tank, it converted 15 tons of chicken manure produced daily into organic fertilizer, with an annual output of 4,000 tons. The products are sold well in surrounding farmlands and orchards, which not only solves the problem of chicken manure pollution, but also brings considerable economic benefits. After using this equipment, a poultry farming cooperative in Vietnam saved more than 50,000 US dollars in environmental protection treatment costs annually, and increased income through the sale of organic fertilizer, achieving a win-win situation of environmental and economic benefits.

We provide multi-language operation interface customization, localized installation and commissioning, and 24-hour after-sales response services. Choose a more efficient, environmentally friendly and competitive chicken manure treatment solution! Contact us now to get exclusive quotes and technical solutions!

Prev: High-efficiency fermentation crawler chicken manure compost turner Next: Organic fertilizer compost turning production line