Organic fertilizer compost turning production line

News June 30, 2025

The demand for agricultural organic fertilizer has surged, but traditional production methods face problems such as low efficiency and heavy pollution. The organic fertilizer compost turning production line we launched integrates four core equipments: solid-liquid separator, compost turner, crusher, and screening machine. It works in a full-process collaborative operation to create an efficient and environmentally friendly organic fertilizer production solution for enterprises.

Solid-liquid separator: Pioneer in raw material pretreatment. The solid-liquid separator in the first process of the production line adopts spiral extrusion and filter separation technology. For high-humidity raw materials such as livestock and poultry manure, the dehydration rate can reach 75% – 85%, and the moisture content of the separated solid material is reduced to 50% – 60%, meeting the optimal humidity conditions for subsequent fermentation. At the same time, the separated liquid can be used as liquid fertilizer or irrigation water after treatment, maximizing resource utilization and reducing environmental pollution.

Compost turner: the core engine of efficient fermentation. The crawler compost turner is equipped with a powerful drive system and propeller blades, which can operate freely in complex terrain and can turn a 3-5 meter wide and 2 meter high pile at a time. Built-in temperature and humidity sensors and intelligent control systems monitor the fermentation status in real time and automatically adjust the frequency of composting, which increases the fermentation efficiency by 60%, shortens the original fermentation cycle of 20-30 days to 8-10 days, and accelerates the transformation of organic waste.

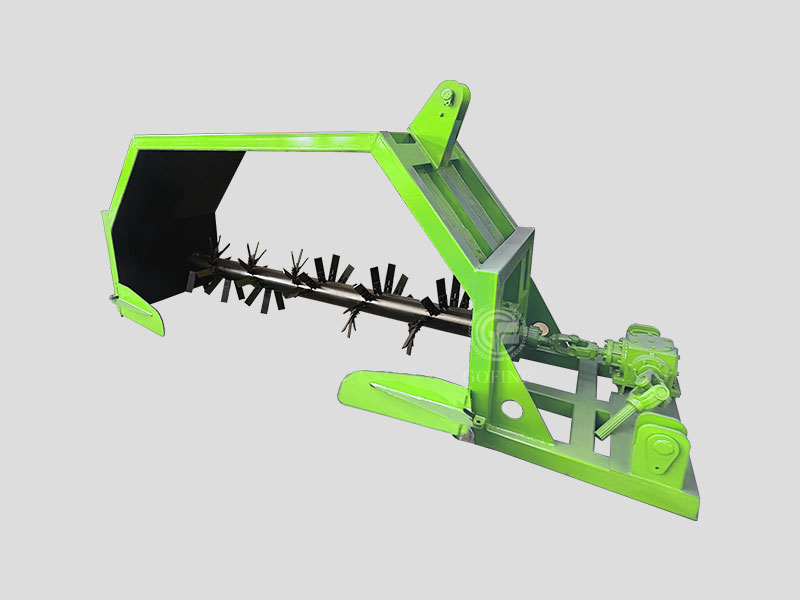

Crusher: key equipment for particle refinement. The matured materials are processed by the crusher. The high-hardness alloy blades and high-speed rotating rotors can crush the block materials to a particle size of 3-10mm, and the crushing efficiency is increased by 50%. According to the needs of different organic fertilizer products, the crushing particle size can also be adjusted to provide high-quality raw materials for subsequent granulation or direct use.

Screening machine: the last line of defense for quality control. The drum screening machine accurately screens the crushed materials through multiple layers of screens, separates unqualified large particles and dust, and ensures that the uniformity of the finished particles reaches 99%. The large particles screened out can be returned to the crusher for secondary processing, achieving zero material waste and ensuring the stable quality of each batch of organic fertilizer.

Full-chain collaboration, green and energy-saving. The four major equipment are seamlessly connected through the PLC intelligent central control system to achieve fully automated operation from raw material processing to finished product output. The fully enclosed structure is equipped with a dust removal and deodorization device, and the dust emission is less than 10mg/m³; the waste heat recovery system recycles the fermentation heat energy, and the energy consumption is reduced by 35%, which fully meets the international environmental protection standards.

Real cases witness strength. After a Vietnamese agricultural group introduced the production line, it converted chicken manure and sugarcane bagasse into organic fertilizer, and the annual output jumped from 8,000 tons to 30,000 tons. The product is sold well in Southeast Asia due to its uniform particles and significant fertilizer effect; after an ecological farm in Africa used it, it not only solved the problem of manure treatment, but also increased its annual income by more than 600,000 euros through the sale of high-quality organic fertilizers.

We provide multi-language operation interface customization, localized installation and commissioning, and 24-hour after-sales response service. Choosing an organic fertilizer compost turning production line is choosing a more efficient, smarter and more competitive green production solution! Contact us now to get exclusive quotes and technical solutions!

Prev: Intelligent and efficient chicken manure fermentation tank Next: Farm manure treatment and composting equipment