Setting off for Kazakhstan! Manure turning machine helps Central Asia

News August 7, 2025

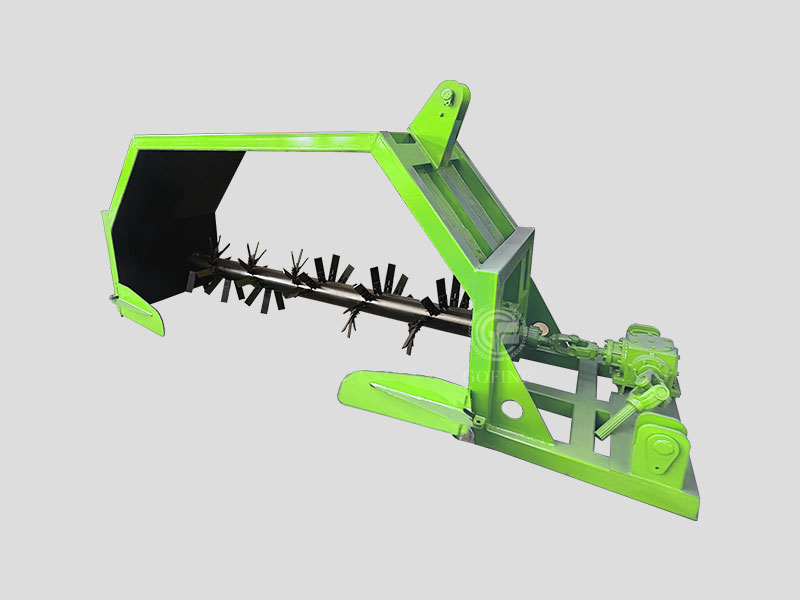

Last week, the manure turning machine custom-made by our factory for a Kazakhstani client departed via the Alashankou Port and will travel 3,000 kilometres to reach the Central Asian steppes. This equipment is specifically designed for large-scale livestock farms in the region, capable of efficiently processing cow and sheep manure, marking another step forward in the application of Chinese manure treatment equipment in the Central Asian market.

To address Kazakhstan’s temperate continental climate and ranch characteristics, the equipment underwent three customised upgrades. It features a widened track design (ground contact width of 450mm) to adapt to the soft terrain of grassland ranches and prevent getting stuck; the turning teeth are made of high-chromium alloy material, tested for low-temperature toughness at -30°C to ensure they do not break in harsh cold conditions; The equipment is equipped with an intelligent temperature control system that automatically adjusts the turning frequency based on external temperature — increasing the number of turns during high summer temperatures to accelerate decomposition and reducing energy consumption during low winter temperatures, maintaining the manure decomposition cycle within 15–20 days.

Pre-shipment factory test data is impressive: the equipment can turn over 800 cubic metres of manure per hour, with a coverage width of 4 metres and a turning depth of 1.2 metres, ensuring thorough air exposure between layers of the manure pile, achieving 30 times the efficiency of traditional manual turning. Testing shows that the moisture content of the treated manure decreases from 75% to 30%, with an organic matter retention rate of 90%, fully meeting Kazakhstan’s organic fertiliser standards.

To ensure safe long-distance transportation, the team has developed a detailed logistics plan: core components are packed in anti-vibration wooden boxes, wear-prone parts like turning teeth are reinforced separately, and the control cabinet is treated for moisture and dust resistance; Russian-language operating manuals, maintenance diagrams, and a common spare parts kit (including 10 types of wear-prone components such as bearings and seals) are provided with the shipment to facilitate post-installation maintenance.

‘This equipment will help us resolve the issue of manure accumulation at the farm.’ The customer representative stated after inspecting the equipment that their farm raises 5,000 beef cattle, and the annual disposal of 30,000 tonnes of manure has always been a challenge. After the equipment is put into use, it will not only eliminate manure odours but also produce organic fertiliser for nearby wheat fields, with an expected annual increase in revenue of up to 150,000 USD.

The after-sales service system is being implemented simultaneously: We have partnered with a local agricultural machinery repair company in Kazakhstan to provide on-site support within 48 hours; we have also established a Russian-language technical hotline and remote diagnostic system to ensure stable operation of the equipment after deployment.

This shipment is a snapshot of China-Kazakhstan agricultural equipment cooperation. We will continue to focus on the needs of the Central Asian market, optimising the equipment’s cold resistance and adaptability, and providing more Chinese solutions for manure resource utilisation along the Belt and Road Initiative.

Prev: Departing for Brazil! Cow Manure Fermentation Tanks Next: 15 cubic meters of manure fermentation tank for Indonesian customers operates stably