15 cubic meters of manure fermentation tank for Indonesian customers operates stably

News July 29, 2025

The 15 cubic meters of fermentation tank purchased by the Indonesian organic fertilizer processing plant from our company in 2023 has become the core equipment for the synergistic fermentation of local palm pomace and cow dung after more than a year of actual operation. This equipment converts agricultural waste that was originally difficult to handle into high-quality organic fertilizer, providing an efficient solution for the circular development of Indonesia’s tropical agriculture.

This fermentation tank is designed specifically for the high temperature and high humidity climate characteristics of Indonesia. The tank body adopts a double-layer insulation structure, and with the intelligent temperature control system, the internal fermentation temperature can be stably controlled at 55-65℃ under the external environment of 35-40℃ – this temperature can not only kill the bacteria and insect eggs in the palm pomace (sterilization rate 99.9%), but also maintain the activity of microorganisms, allowing the material to complete the decomposition within 7 days, which is 60% shorter than the local traditional composting cycle.

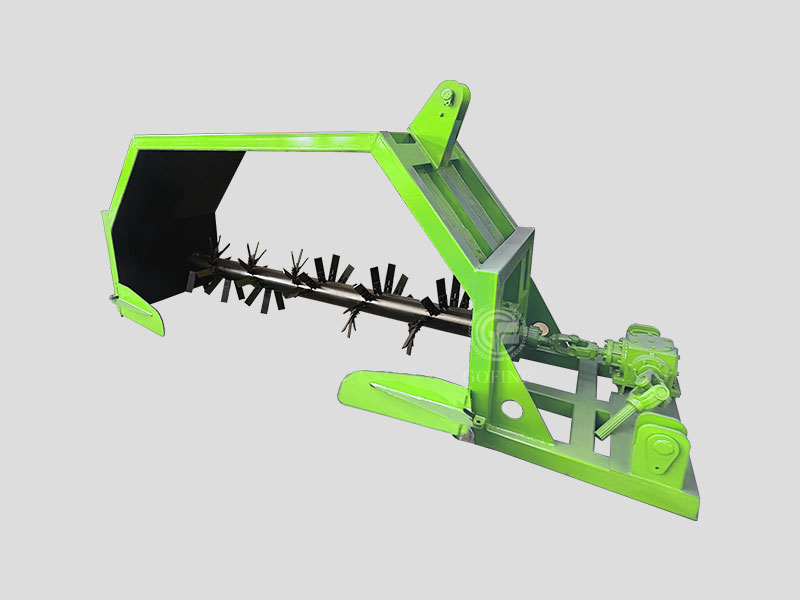

Taking into account the characteristics of the main fermentation raw materials in Indonesia, the equipment optimizes the stirring and aeration system. Palm pomace fibers are coarse and cow dung has high viscosity. The special spiral stirring blades can fully break up the materials to avoid agglomeration. The aeration system maintains the oxygen content of the materials in the optimal range of 10%-15% through precise oxygen supply, solving the problem of incomplete decomposition caused by insufficient oxygen supply in traditional fermentation. Trial production data show that the organic matter content of the fermented organic fertilizer reaches 45%, far exceeding the local organic fertilizer standard.

The durability and adaptability of the equipment have also withstood the test. The tank body is made of 316 stainless steel, and the corrosion resistance in tropical climates is improved by 50%; the anti-blocking feed port and automatic cleaning system are equipped to reduce the maintenance trouble caused by palm pomace fibers. After more than a year of operation, the equipment failure rate is zero, the fermentation efficiency is always stable, a single batch can process 15 cubic meters of materials, and the annual output of organic fertilizer reaches 8,000 tons.

“This fermentation tank helped us solve the big problem of palm fruit residue treatment.” The customer said in the follow-up visit that after the organic fertilizer produced by fermentation was used in his own palm plantation, the soil organic matter content increased by 20%, the palm fruit production increased by 12%, and the waste treatment cost was reduced by about US$50,000 per year. At present, the customer has planned to expand the production scale and consider purchasing another equipment of the same model.

From the initial analysis of raw material characteristics to the later remote technical support, we provide localized services throughout the process. The equipment operation interface supports Indonesian, and the technical team helps local employees quickly master the operation skills through online training. This successful application once again proves the adaptability of Chinese fertilizer equipment to the resource utilization of agricultural waste in tropical regions.

We will continue to deepen the fermentation needs of different regions, provide equipment solutions that are more in line with local realities, and help the development of the global agricultural circular economy.

Prev: Setting off for Kazakhstan! Manure turning machine helps Central Asia Next: Malaysian Customers Purchase Crawler Cow Dung Compost Turner On Site